Melting-holding furnace

ADVANTAGES AND FEATURES

The furnace which is designed by COMETAL can ensure long-term operation and easy maintenance. Combustion is achieved by high-speed burners to increase melting and efficient ceramic regeneration burners to reduce energy consumption.

Loading doors are built in separate units, allowing thermal expansion due to its special design. The furnace is airtight by contacting amid stainless steel plates.

In the process of casting, the adjustment of furnace inclination is controlled by a special proportional valve which can be used as a function of adjusting the casting speed of metal flow rate.

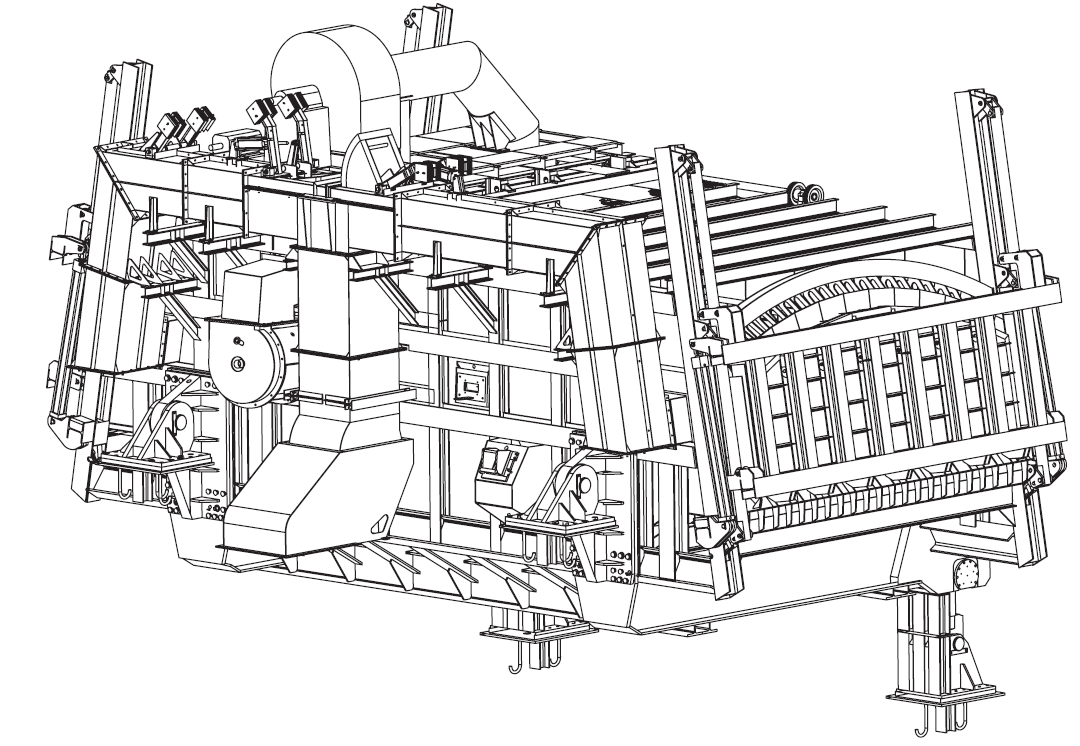

Melting furnace with double chambers

ADVANTAGES AND FEATURES

Any model that can be obtained from time to time can be loaded into the furnace (including dirty metal waste which is polluted with oil, paper or paint)

The air in the furnace is continuously monitored to ensure maximum release.

Pollution with low pollution rate can be reduced by optimizing heat generation and allowable heat energy operation through partial flame afterburning.

In addition, the use of electromagnetic stirring induces convective motion in the melting pool, which adds further advantages, including reduced need for mechanical stirring.

Heat exchange with loading, by maintaining a direct current of the liquid.

Treated with a high liquid level, the melting time is reduced by nearly 20% by utilizing the advantage of high thermal energy accumulation.

The surface movement of liquid limits the formation of dregs and promotes their elimination.

Energy consumption can be reduced by 10-15%.

The temperature of the molten pool should be uniform so as to avoid typical superheating on the surface and obtain a homogeneous alloy without precipitation.

It is determined that a two-hearth furnace with agitator improves the quality and metallurgical output of the casting process.

Casting

ADVANTAGES AND FEATURES

Design of equipment aims to achieve maximum reliability and simplicity for operation and maintenance.

In fact, the special technical features have fast accessibility for log maintenance

The high metallurgical quality of casting logs, on the other hand, is the result of in-depth research on cooling system, which leads to the optimization of equipment operation parameters. Surface quality is also guaranteed by the accuracy of the casting table transmission and the possibility of using lubricants.