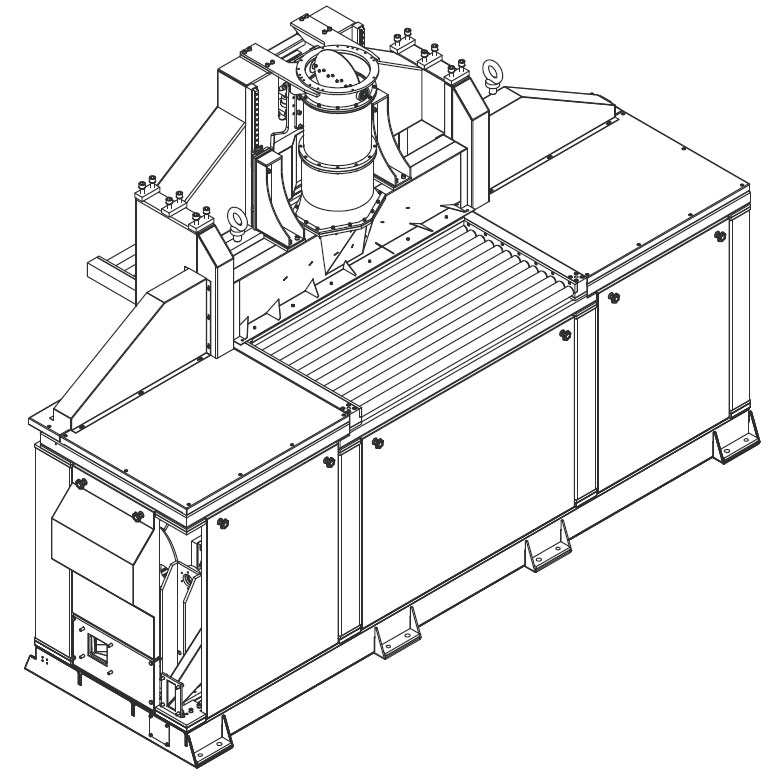

Cutting table

The semi-automatic management of table movement ensures maximum operator safety.

The roller movement, which is controlled by inverters, permits regular acceleration as a function of the weight of the profile, thereby advoiding abnormal collisions against the cut stopper.

The adsence of shocks guarantee perfect alignment of the profiles and replicability and precision in producing the desired length.

Evacuation of the cut layer towards the stacking area takes place without intervention by the operator.

It is also possible to have automatic scraps evacuation(head and/or tail of profiles) on the scrap cutting line.

Finishing saw

The quality of the cut is guaranteed by the precision construction and optimized lubrication

Ease in maintenance and reduced blade changing time are the result of an attentive design.

The base is realized in sound absorbent material.

The high standards of safety employed guarantee maximum operator safety.

Variants are available with overhead and underneath cutting for use with light or heavy sections

The efficient scraps suction system, working together with the “air mover” system installed on the cutting table, ensures perfect cleaning of the profile ad cutting area.

Large size versions are available for maximum profile layer dimensions of up to 300mm(H)x1000-1200-1400-1600mm(L).