|

Cutting type and Classification |

||||

|

Press capacity |

billet size |

Non-extrusion time |

||

|

|

long [mm] |

Diameter: [mm]/inch |

without exhaust cycle |

With exhaust cycle |

|

11 |

700 |

127 / 5” |

10 |

12 |

|

13,2 |

800 |

153 / 6” |

11,5 |

13,5 |

|

15,4 |

850 |

153 / 6” |

12 |

14 |

|

18 |

980 |

178 / 7” |

13 |

15 |

|

20 |

1100 |

178 / 7” |

13 |

15 |

|

25 |

1200 |

204 / 8” |

13,5 |

15,5 |

|

28 |

1300 |

204 / 8” |

13,5 |

15,5 |

|

33 |

1300 |

228 / 9” |

134 |

16 |

|

36 |

1300 |

228-254 / 9-10” |

14 |

16 |

|

40 |

1400 |

254-280 / 10-11” |

15 |

17 |

|

44 |

1400 |

254-280 / 10-11” |

15 |

17 |

|

50 |

1400 |

355 / 14” |

17 |

19 |

|

55 |

1400 |

355 / 14” |

17 |

19 |

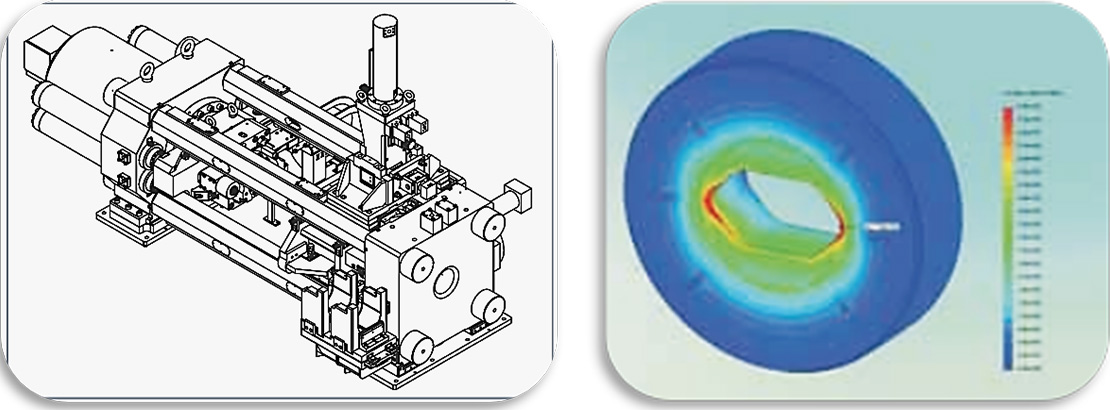

Features of mechanical, hydraulic and electrical parts

Features

All the main components are made of forged steel to ensure the maximum quality and reliability of the parts

The columns are prestressed on the whole length, at a value of 20% greater than the value induced by the maximum extrusion force,to reduce the elongation during operation, thereby significantly increasing their resistance to fatigue.

F.E.M. analyses are regularly performed on the parts most subject to fatigue in order to guarantee the necessary useful life and to calculate the status of stress and deformation of the platen and the pressure ring, in order to minimize deformations of the die during extrusion.

The container is thermo-regulated to guarantee improved control of processing.

The lateral displacement of the stem allows lubrication of the dummy-block during introduction of the billet into the container, without increasing the dead cycle time.

Mounting of the lateral and container cylinders on the sides of the press allows a quick replacement of the container and good accessibility for maintenance operations

The longitudinal movement(tilting) of the shears guarantees a perfect cut that grazes the surface of the die and avoids scratches of the remaining material during the return phase, which could create defects in the extruded profile.

The optional “Bolster shear” can be installed to permit cutting of the profiles between the bolster and the die for easy cleaning operations or, possibly, re-use the bolster with the next die.

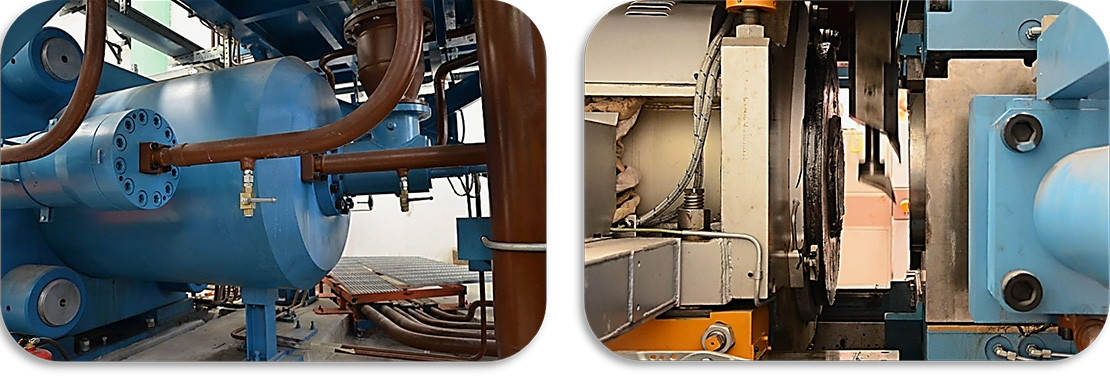

Hydraulic characteristics

All of the hydraulic components the press is equipped with are manufactured by highly qualified suppliers, such as Rexroth, Oilgear, pall,etc., which is a guarantee of the utmost reliability of the parts and availability of spare parts. The following special features are foreseen.

The hydraulic circuit is realized according to the “one manifold” philosophy and is manufactured from forged steel to reduce joints in the piping to a minimum and facilitate maintenance.

The drop in pressure through the logical elements is limited in order to avoid heating oil.

Oil speed through the output and suction pipes is kept low in order to avoid heating and excessive energy loss

Electronice

Management of sequences and relevant hydraulic plant alarms (pump, tank, etc) with the possibility of blocking the press in the event of serious anomalies.

“Slow-end function” to automatically slow down the stem when extrusion is completed, depending on the type of profile and extrusion speed, to avoid profile stretching.

Automatic control of butt end thickness.

Automatic cycles for the extrusion of ½,1,2 or more billets with the die emptying cycle and automatic selection of the first billet for the die filling cycle.Automatic”call” system for billets, in accordance with the position of the cylinder(which can be selected directly from the control panel.)

Container temperature control performed with heating elements and air-cooling.

Anomalies and alarms management with automatic processing sequence stop in situation at risk.

The diagnostics of the machine provides visualization on the control panel of the reasons for eventual operational problems

Possibility to perform a dry cycle test. The function allows performance of a complete cycle without billets, for maintenance purposes